Why quality alone isn’t enough – and how CASS is changing the game

In the journey of bringing Vietnamese agricultural products to the global market, post-harvest preservation is no longer a supporting step — it’s a critical turning point. No matter how well something is grown, if it is not preserved properly, it risks being rejected at the border, erasing the entire value chain behind it. This is no longer just a warning — it’s a harsh reality for Vietnam’s agriculture sector.

Hard numbers reveal the truth

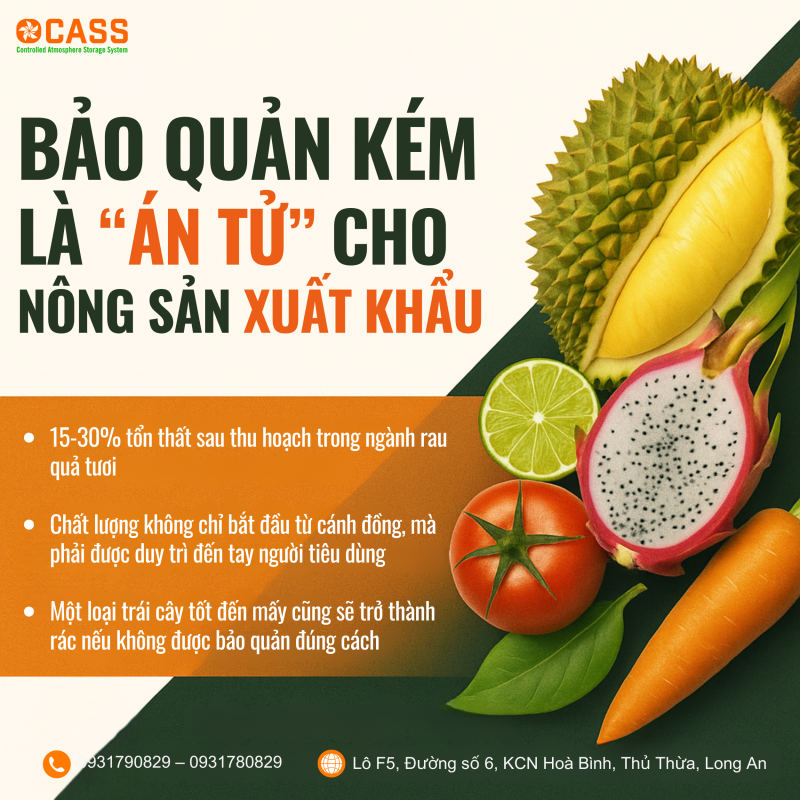

According to the Ministry of Agriculture and Rural Development, post-harvest losses in Vietnam’s fresh fruit and vegetable sector range from 15% to 30%, and in some cases, even up to 40%. This is not just a waste of resources — it’s a direct loss for farmers, cooperatives, and exporters. Every shipment returned due to mold, spoilage, or excessive residue damages our credibility and undermines national brand trust.

Even products like durian, banana, mango, or dragon fruit — which meet export codes and planting region certifications — are often denied clearance because storage conditions fall short of international shipping requirements or lack full traceability.

Quality must go beyond the farm and reach the consumer intact

Many exporters heavily invest in farming techniques, crop varieties, and certifications like GAP, but they underinvest in preservation and logistics infrastructure. Meanwhile, key export markets like the EU, Japan, South Korea, and the U.S. require not just “clean harvests,” but maintained freshness, safety, and consistency throughout long international journeys.

Even the best produce becomes worthless without proper preservation.

Vietnam urgently needs a “preservation revolution”

While countries like Thailand, New Zealand, and Chile have long implemented CA storage systems, advanced cold chains, and end-to-end logistics integration, much of Vietnam’s produce still depends on manual packing, traditional warehouses, and chemical-based treatments to delay spoilage.

It’s no surprise, then, that our export values remain lower, even for the same crops.

CASS – A technological answer to this painful challenge

In response to this critical gap, CASS (Controlled Atmosphere Storage System) was established as a clean and advanced preservation model tailored for Vietnam’s export needs.

Instead of using chemicals or unsafe additives, CASS applies Controlled Atmosphere (CA) technology — precisely regulating O₂, CO₂, humidity, and temperature to:

- Extend shelf life by 2 to 4 times

- Reduce post-harvest waste to below 5%

- Enable storage while waiting for better market prices

- Meet export standards for EU, U.S., Japan, and Korea

- Ensure full traceability with modern digital software

Additionally, CASS integrates automated robotic systems (ASRS) and smart inventory management to eliminate human error, enhance safety, and increase transparency — all of which are highly valued by international buyers.

From preservation to export: Every step must meet the global standard

Vietnam cannot hope to compete globally if we rely on outdated preservation technology and the mindset that “growing is enough.” We need a modern preservation ecosystem that is clean, traceable, cost-effective, and ready for export.

CASS proves that this transformation is not only possible — it’s already happening.

If we don’t invest in proper post-harvest preservation, our agricultural efforts will continue to “die at the border.”

__________

CASS – Preserving quality, elevating value, and unlocking a sustainable export future for Vietnamese agriculture.

📍 Lot F5, Street No. 6, Hoa Binh Industrial Zone, Nhi Thanh Commune, Thu Thua District, Long An Province

🌐 Website: www.cass.vn

📞 Hotline: +84 931790829 – +84 931780829

📧 Email: cass@cass.vn