Why Rapid Cooling is Essential:

Businesses dealing in fresh produce know that cooling slows down respiration, reduces nutrient loss, and lowers heat generation, extending the shelf life of fruits and vegetables. Achieving rapid cooling is crucial because the sooner respiration is reduced, the longer the produce lasts.

Why Over-Cooling Must Be Avoided:

Every type of produce has a specific temperature range for storage. Cooling below this range can cause cold damage, particularly in tropical regions like Vietnam, where produce often has a higher minimum storage temperature. Therefore, storage facilities must achieve rapid cooling while avoiding temperatures that are too low for the produce.

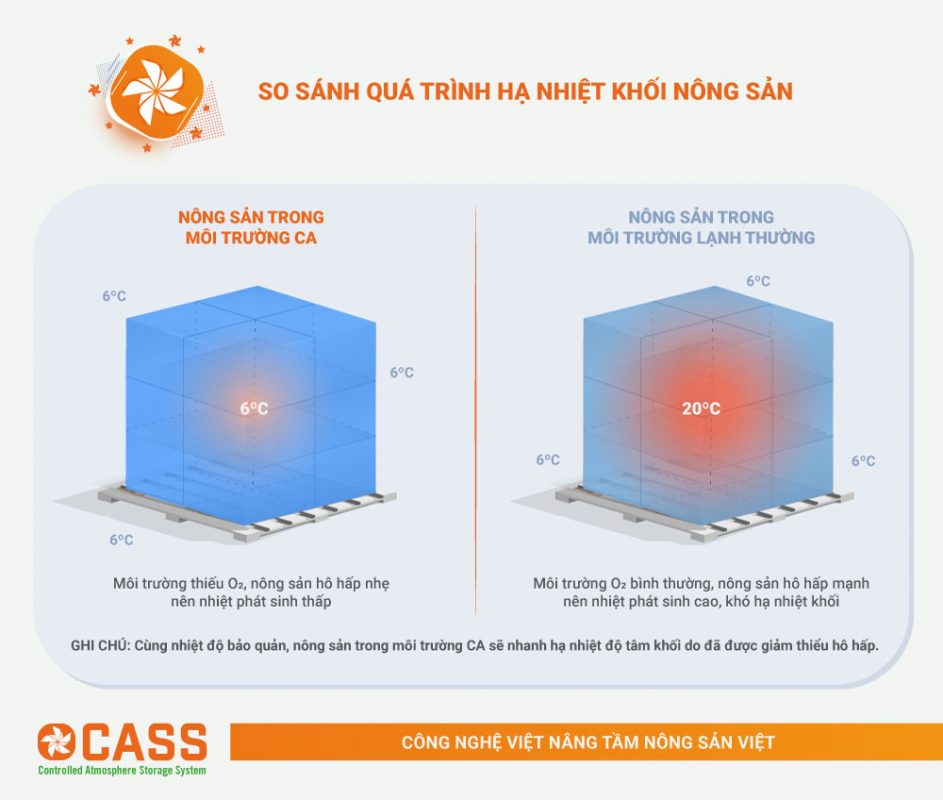

In commercial storage conditions, this is challenging because produce is stacked in large blocks on pallets, obstructing cold air from penetrating the core. Additionally, ventilation fans are usually positioned in a few spots, causing strong airflow near the fans and potential cold damage, while areas farther from the fans may have inadequate airflow, making it difficult to cool the entire block effectively. Furthermore, until the temperature decreases, respiration rates and heat generation remain high, complicating the cooling process compared to the small, well-ventilated test conditions.

For instance, dragon fruit has a recommended storage temperature of 6°C, but many cold storage facilities cannot maintain this temperature without causing damage within a few days. As a result, these facilities lower the temperature slightly to cool the produce faster, which unfortunately leads to a 20-30% rate of cold damage. Symptoms of cold damage often appear after about 10 days, increasing spoilage rates.

How Does CASS Solve These Problems?

At CASS, these issues are addressed comprehensively through the following solutions:

- Reducing Heat Generation with CA Technology: The Controlled Atmosphere (CA) environment at CASS, akin to a giant nitrogen chamber, creates low oxygen conditions that immediately reduce respiration and prevent heat generation within the produce.

- Even Pallet Spacing with Robotic Systems: Pallets are evenly spaced using robotic systems, ensuring proper ventilation and ease of airflow.

- Extensive Ventilation System: Thousands of ventilation points with optimally adjusted airflow speeds ensure uniform and rapid heat exchange throughout the storage facility.

With these integrated solutions, CASS can cool fruit blocks rapidly without excessively lowering the storage temperature, a critical step in preserving produce quality and extending shelf life without causing damage.

• Hotline/Zalo: 0931790829 – 0931780829

• Email: cass@cass.vn

• Website: cass.vn

• Fanpage: CASS – Kho bảo quản nông sản tươi bằng công nghệ CA

• Địa chỉ kho CASS: Lô F5, Đường số 6, KCN Hoà Bình, Huyện Thủ Thừa, Tỉnh Long An.